2019

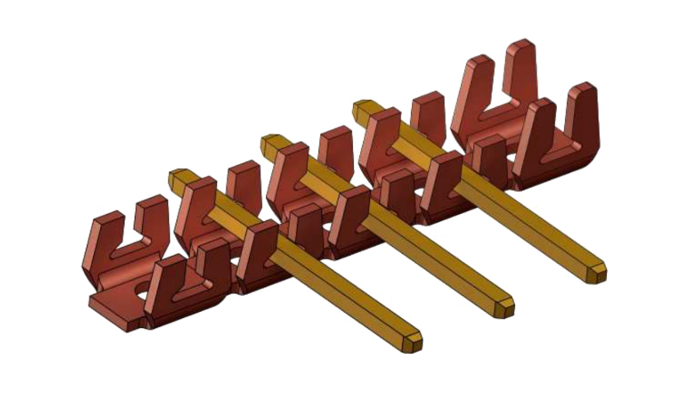

SM Contact invites you to booth A5.300, Messe München in November 12-15 at productronica. We will show how our offsprings became more automated, better adaptable to various tasks and plug-and-play installable. We will reveal details of working process from simulation of a connection – through design and manufacturing of equipment – to the customer quality report.

Read More